The project is being realized by TekhInvest Service. MIG Series gas turbine plants were developed on the base of GTD-1250 gas turbine designed and manufactured by Klimov JSC. The gas turbine is used as T-80 tank power package. On the base of this gas turbine simple and cogeneration power plants (800 and 1000 kW) were developed. These plants can operate on the base of various types of fuel such as natural gas, associated petroleum gas, coal-bed methane, biogas and others. The pilot power plant is installed on the site of boiler-house of the enterprise for carring out of testing and engine development.

Новости

Gas pumping unit consists of compressor plant in separate casing with opposed piston compressor and drive with all necessary auxiliary equipment. PKU016 complete compressor plant will operate as GPA-3 gas pumping unit. The customer of the equipment is Sibneftegas PJSC. The unit is intended for natural gas compression. The unit is equipped with Caterpillar G3612 engine rated at 2.64 MW, rotation speed is 750…1000 rpm. KBZ/4 compressor was manufactured by Ariel. Pressure discharge is 11.19 MPa, volumetric capacity is 260.42 thousand m3 per hour. The equipment will be installed in easy-to-assemble building.

Gas pumping unit consists of compressor plant in separate casing with opposed piston compressor and drive with all necessary auxiliary equipment. PKU016 complete compressor plant will operate as GPA-3 gas pumping unit. The customer of the equipment is Sibneftegas PJSC. The unit is intended for natural gas compression. The unit is equipped with Caterpillar G3612 engine rated at 2.64 MW, rotation speed is 750…1000 rpm. KBZ/4 compressor was manufactured by Ariel. Pressure discharge is 11.19 MPa, volumetric capacity is 260.42 thousand m3 per hour. The equipment will be installed in easy-to-assemble building.

Two GPA-16 gas pumping units were manufactured and supplied by Iskra-Neftegas сompressor company for booster compressor station of Beregovoye oil & gas field (Sibneftegas). The first stage of the station is used for gas pressure boosting upstream of Beregovoye-Zapolyarnoye cross-country natural gas pipeline. GPA-16 hangar gas pumping units were developed on the base of NK-16-18STD gas turbine engines rated at 16 MW.

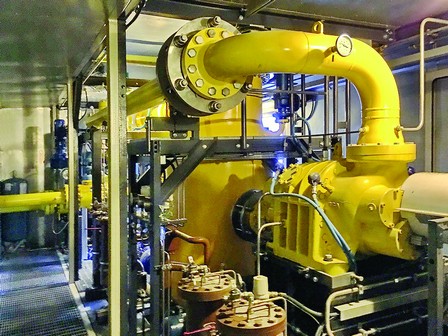

Two plants will be used for transportation of associated petroleum gas of first stage of separation delivered from booster compressor stations of Yuzhno-Vatlorskoye, Vatlorskoye, Suryeganskoye, Verkhnekazymskoye fields and the field named after I.N. Logachev. Compressor plants were developed on the base of oil-flooded screw-type compressors. They will provide final treatment, compression and delivery of associated petroleum gas to the pipeline on a continuous basis under the pressure of 2.2 MPa. The output of each compressor plant is 10000 m3 per hour. All installation and commissioning works for the equipment were carried out by the specialists of Energas Group of Companies.

Two plants will be used for transportation of associated petroleum gas of first stage of separation delivered from booster compressor stations of Yuzhno-Vatlorskoye, Vatlorskoye, Suryeganskoye, Verkhnekazymskoye fields and the field named after I.N. Logachev. Compressor plants were developed on the base of oil-flooded screw-type compressors. They will provide final treatment, compression and delivery of associated petroleum gas to the pipeline on a continuous basis under the pressure of 2.2 MPa. The output of each compressor plant is 10000 m3 per hour. All installation and commissioning works for the equipment were carried out by the specialists of Energas Group of Companies.

UTW signed an agreement with the State Electricity Production Association Belenergo on promising cooperation under the power engineering projects implemented in the Republic of Belarus. Following on from the agreement the parties signed a contract on the Ural Turbine Works’ participation in the reconstruction of Minsk TPP-3 (RUE Belenergostroy is a general contractor under the project).

|

|

Under the contract Siemens supplied gas pumping units developed on the base of SGT-400 gas turbines each rated at 13.4 MW. Gas pumping units are installed in separate buildings. General designer for the project is Kazakh Institute of oil and gas. General contractor of the compressor station is DO KNISG. It is the first stage of the project. Similar units will be supplied to Baykonur, Saksaulsk, Chernak and Karaozek compressor stations of the pipeline. |

Under the contract GrandMotors produced, delivered, installed and commissioned diesel power plant for emergency stand-by power supply of perinatal center in Tambov. GMD550 (GMGen Power Systems) power plant is rated at 400 kW. It was developed on the base of Doosan DP158LDF diesel engine. Power equipment is installed in Sever BKS-1 container. The project was realized under the program of perinatal center in Russia development under the order of Rostech State Corporation. The program specified the construction of 32 new perianal centers during the period of 2013-2016. GrandMotors delivered stand-by power plants to 16 of such centers.