Razdanskaya power plant is the biggest CHP plant in Armenia, its capacity is 1100 MW. The capacity of the fifth power unit being incompleted is 300 MW.

Under the agreement with ArmRusgasprom JSC Engineering and designing centre – New generation Ltd. will fulfill upgrading of the fifth power unit. The company will replace it with combined cycle power unit on the base of Alstom GT13E2 gas turbine with the capacity 179.9 MW and the existing steam boiler. As a result power unit capacity will come up to 431 MW. Assembling and installation will be fulfilled by HPCC-3 company (China). The power equipment will be operational at the end of 2010.

Новости

Progress Company will build power complex for oil refinery works in Volkhov under the turnkey contract. The customer is Volkhovneftehim JSC. Gas engine power plant will be designed on the base of three GE Energy's Jenbacher gas engines JMS 312 GS power units rated at 625 kW each and one JMS 320 GS power unit with the capacity 1063 kW. All the power units will be equipped with heat recovery system.

The power complex also includes two stand-by FG Wilson P1700P1 diesel generating sets rated at 1360 kW each. Generated thermal power will be used for hot-water supply and heating system. Two Vapor steam boilers with the capaity 13.2 t/h will generate steam for technological purposes of the enterprise. The commissioning is scheduled for the end of the year.

Reinforcing its commitment to support the development of Russia’s energy infrastructure, GE Energy has signed an agreement to build a new power technology center in the Kaluga Region that will initially provide services for GE power generation equipment installed in Russia and the Central Asian States. The agreement to construct the technology center was signed with the government of Kaluga Region, the Kaluga Region Development Corporation and the administration of Kaluga City.

The new Kaluga technology center will include an office building and industrial shop, and in its first phase handle the repair and service of GE heavy-duty gas turbine components. GE Energy anticipates that the technology center, once fully operational, will employ between 50 to 100 highly-skilled Russian engineers and service staff. Commissioning and startup is scheduled for the first quarter of 2011.

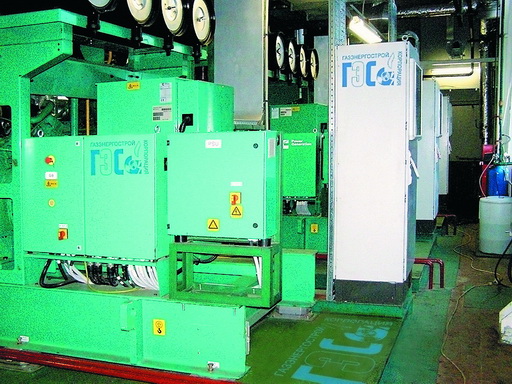

Autonomous CHP plant with the capacity 4 MW of electric and 11.4 MW of thermal power is designed on the base of gas engine power units by GasEnergoStroy Corporation.

Autonomous CHP plant with the capacity 4 MW of electric and 11.4 MW of thermal power is designed on the base of gas engine power units by GasEnergoStroy Corporation.

The power plant fully provides all power requirements of 34 000sqm trading centre in electricity, heat and cold.

The power plant consists of three modular GES-EH1160G gas engine power units rated at 1160 kW of electric and 1457 kW of thermal power each, stand-by GES-E512D diesel generating set with the capacity of 565 kW, four GES-H1750GD hot-water boilers rated at 1750 kW each. The power units feature high total efficiency – 90 %. The application of exhaust gases catalyst purification system makes the power plant meet the strictest ecological standards.

The British energy company, Blue-NG, has placed an order for a series of MAN B&W type 10L35MC-S diesel engines run on bio-liquids. The first four engines will be installed at sites in Beckton and Southall, Greater London, and are intended to supply green, low-CO2 power to the capital by 2010.

The two-stroke, low-speed engines will be built by MAN Diesel’s Polish licensee, H. Cegielski – Poznan S.A. Each engine develops 6,450 kW and has an ISO 3046 efficiency of 48.9 %.This high thermal efficiency is one of the main reasons for Blue-NG choosing MAN Diesel power. The MAN B&W engines’ performance is unrivalled in the 6MW diesel-power segment where normal efficiencies are usually in the range of 42-47 %.

The innovative plant, known as CHiP (Combined Heat and intelligent Power) will be the first of its kind in the world. The engines’ hightemperature waste heat will drive an organic Rankine cycle (ORC) turbine, while low-temperature waste heat will be used in a natural-gas, pressure reduction station where the heat will drive turbo expanders. The plant’s total net electrical efficiency will therefore peak at above 80 %.

The client, Blue-NG, is a joint venture between the National Grid, the UK’s gas and power-distribution company, and 2OC Ltd., a company well known in geothermal energy and natural-gas pressure-reduction station projects. The first MAN B&W 10L35MC-S engine is due for ex-works delivery in December 2009, with the remaining engines due to follow thereafter at three-month intervals.

The company has won Gaskomplektimpex Ltd. tender to sign contracts for the delivery of power equipment. Under the project the company will deliver 9 power stations with the total capacity 93 MW for compressor stations of Bovanenkovo-Ukhta gas pipeline. Gas engine power plants will satisfy all power requirements of compressor stations. Each power plant will consist of 5-7 gas engine power units rated at 1.1 - 1.5 MW each and stand-by diesel power plants with the capacity 0.6 - 1 MW each.

By the time of being Zvezda-Energetika has delivered more than 310 power units with the total capacity 214 MW for Gasprom JSC projects. The commissioning of the gas-main pipeline is scheduled for the end of 2011.

Mitsubishi Heavy Industries, Ltd. (MHI) has developed and begun operational verification testing of the "MACH II-SI," a new gas engine featuring enhanced energy efficiency and reliability. The MACH II-SI was developed based on the company's existing "MACH-30G," which many units have been sold in Japan; but whereas the forerunner uses a "micro-pilot ignition" system, the new MACH II-SI adopts a spark ignition (SI) system that eliminates the need for auxiliary liquid pilot fuel such as light oil.

In developing MACH II-SI, MHI focused on further enhancement of the efficiency leveraging its abundant experience accumulated in its existing engines. As a result, the new engine has achieved efficiency – combining power generation and heat energy recovery via steam – of 66.1%*, the world's highest level among 6,000 kilowatts (kW) class engines, in which electric power generation efficiency has been improved by 1 percentage point. MHI expects the MACH II-SI series, which power output ranges from 3,650 kW to 5,750 kW, will significantly contributes to increasing needs for CO2 emission reduction.

To enhance overall efficiency, MHI focused on enhanced heat recovery in steam generation and effective utilization of exhaust gas energy. The company also has shortened lead-time to reach full load after engine start by 50%, which contributes to enhance load-following capability. In order to boost power generation efficiency, MHI redesigned the combustion chamber, including the cylinder cover and piston. By optimizing formulation of the fuel-air mixture, as well as improving the pre-chamber's shape and fuel-air mixture ratio, the company has raised combustion efficiency and reduced thermal loss.