Siemens Energy has been awarded a contract for turnkey construction of the Santo Domingo de los Olleros simple cycle power plant in Peru with an option for a combined cycle plant in the next phase. Purchaser is Peru-based Termochilca SAC. The simple cycle plant is scheduled to start commercial operation in late 2012.

Siemens Energy has been awarded a contract for turnkey construction of the Santo Domingo de los Olleros simple cycle power plant in Peru with an option for a combined cycle plant in the next phase. Purchaser is Peru-based Termochilca SAC. The simple cycle plant is scheduled to start commercial operation in late 2012.

With the Siemens high-efficiency power plant, Termochilca aims to meet the growing power demand in Lima. The order volume is approximately USD80 million.

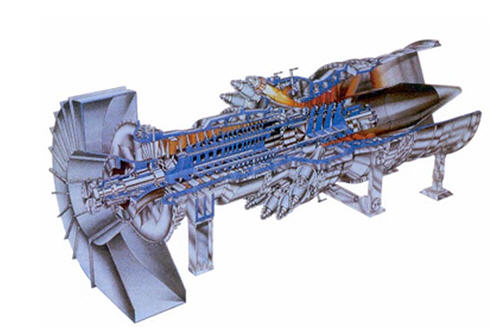

Power plant, with an installed capacity of approximately 200 megawatts, will be located in the Chilca district in Cañete province, Lima region, Peru. Siemens will be responsible for full turnkey supply of the plant, which includes engineering, procurement, and construction of the plant. The main equipment to be supplied includes an SGT6-5000F gas turbine, electric generator SGEN6-1000A, and the entire electrical and SPPA-T3000 instrumentation & control equipment.

Siemens also signed a long-term service agreement with Termochilca, which will provide Termochilca with reliable plant service.

The station will generate electric and thermal power for the needs of greenhouse complex of Teplitsy Ramenskiye Ltd. The station consists of four

The station will generate electric and thermal power for the needs of greenhouse complex of Teplitsy Ramenskiye Ltd. The station consists of four