The transportation of the equipment from Genoa sea port to the site of the station was carried out by Natrex Group. The total weight of transported equipment was 3500 tons.Electric output of the station will be 264 MW.

The transportation of the equipment from Genoa sea port to the site of the station was carried out by Natrex Group. The total weight of transported equipment was 3500 tons.Electric output of the station will be 264 MW.

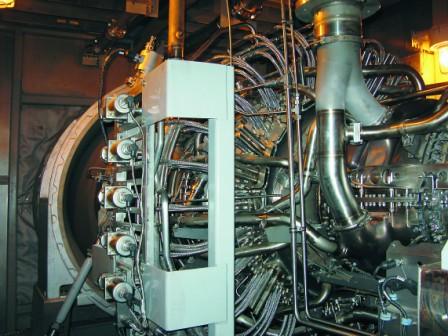

It will consist of two Ansaldo Energia V64.3A gas turbine plants with air-cooled electric generators, two ZiO Podolsk E-99.6 heat recovery steam generators,

T-48/62-7.4/0.12 steam turbine equipped with TZFP-63-2MUZ9 air-cooled electric generator delivered by Kaluga Turbine Works. General contractor for the project is TEK Mosenergo.

The project was realized under the investment program of

The project was realized under the investment program of  The contract for equipment delivery was signed by

The contract for equipment delivery was signed by