The production of the 4+1 combustion chamber cover has been mastered by the Rotor plant (Gazenergoservice JSC). It limits the volume of the combustion zone and together with the fuel injectors forms the aerodynamics of the torch. The product, which is complex in geometry, is a flow separator, in the end part of which more than 2000 cooling holes are made at different angles.

Новости

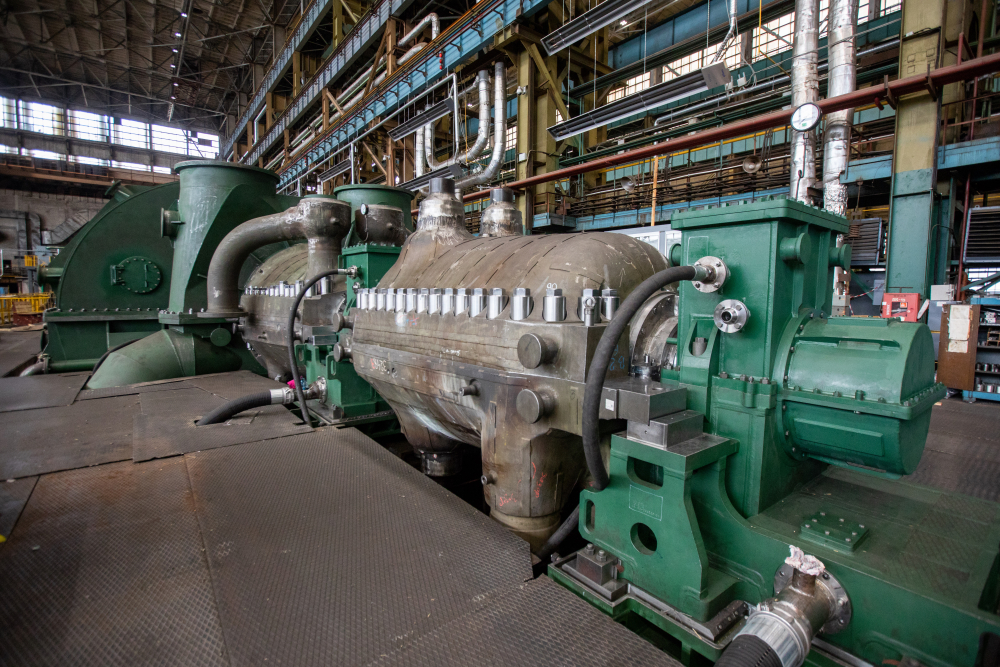

T-190/225-12.8 steam turbine was manufactured at the Leningrad Metal Plant (LMZ, Power Machines JSC) as part of the modernization of Surgut GRES-1 (OGK-2). The steam turbine has passed factory tests in the presence of representatives of the customer. It will replace steam turbine K-210-130 steam turbine of unit No. 13, reached the end of its service life, manufactured by LMZ and worked at the station for more than 40 years. Due to a number of design solutions in the T-190/225-12.8 turbine, the possibility of steam extraction for heating up to 275 Gcal/h is realized. The reliability of the turbine has increased, and overhaul period has been extended to 6 years.

Production of a modular composting complex has been completed at the Kurgan plant of integrated technologies (Intertechelectro Group). The equipment of its own design, which has no Russian analogues, is intended for use at industrial enterprises and waste management facilities. Currently, the complex is undergoing pilot operation, after which its serial production will begin at the plant. The composting complex consists of closed containers and a technical module, in which the control unit, filtrate and air purification systems are located.

The 400 kW container-type power plant is based on the SGE24 SL (Siemens Energy) gas engine. The plant is equipped with gas pollution control and gas fire extinguishing systems, automatic fire alarm systems.

The repair of the second combined-cycle gas plant has been completed at the power plant – the CCGT has started operating at nominal mode. 150 employees of the plant and 13 specialists of Mitsubishi Power, the manufacturer of the main equipment of the power station, took part in the repair work. As a result of the work carried out, the stability of energy production is ensured. The contract for the supply of equipment and turnkey construction of a 450 MW combined cycle power station was implemented by a consortium consisting of Mitsubishi Power and Mitsubishi Corporation together with the Turkish company Calik Energi.

The contract for the supply of power equipment is being implemented with ACWA Power Corporation (Turkey). Mitsubishi Power, a subsidiary of MHI, supplied two M701JAC gas turbine power units with an electric capacity of 557 MW each. They will be installed at a combined cycle power plant under construction with a capacity of 1,500 MW.

According to the results of a survey of the largest Russian companies in the energy industry, the enterprise Modern gas turbine technologies LLC was recognized as the best among suppliers of gas turbines for the fuel and energy sector. The TEK-Rating Agency conducts annual surveys of generating and grid companies that evaluate manufacturers of energy equipment. The main objective of the rating is to identify the best manufacturers of products and service providers through a direct survey of consumers. This contributes to the development of the competitiveness of the fuel and energy equipment market, increasing its transparency and openness, and the exchange of information about suppliers between fuel and energy companies.